Professor Myrol Flutensnoken's Patented self-loading, combusting vapor-aether slug projector...

Better known as the fully functional steampunk AK47.

Let’s look at the source material:

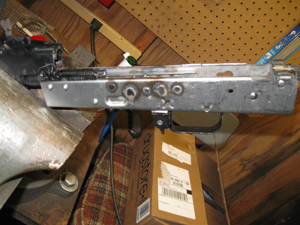

This is a previous gun I built in the garage.

This is the AK47, the preferred weapon of your enemies, and it makes a very distinctive sound when fired at you...

Sorry, wrong script.

Anyway, the AK is a weapon designed by crude, semiliterate peasants for crude, illiterate peasants. It dates from 1945-1947, but the construction methods are considerably more primitive. I was looking at one of my previous builds, and it occurred to me the riveted construction, phosphated black steel and brute force mechanics were almost steampunk. Then it hit me.

It’s halfway to being steampunk already, but it needs a little dressing up from its gutter-behind-the-servants’-entrance looks.

So, let’s start building an AK.

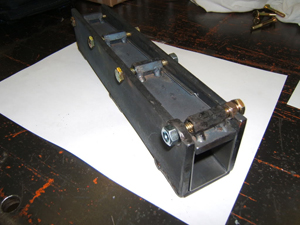

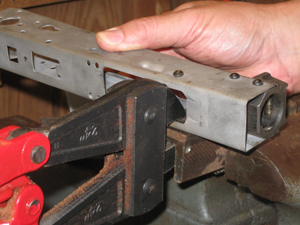

This is a .040 sheet of 4140 steel with some punching and drilling.

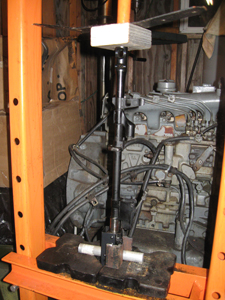

Now we crush it around a form in a 2 ton press:

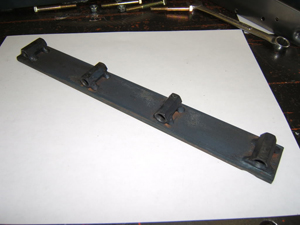

Hammer over the top rails...

Drill rivet holes, and neaten the trunnion and fire control group holes...

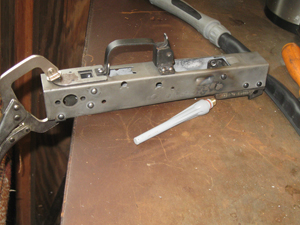

(This is from an underfolder build I did at the same time. There are several ways to build an AK)

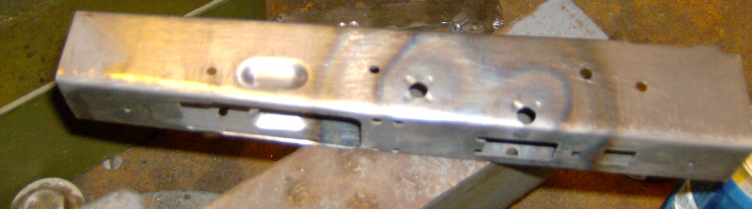

The bolt rails are traditionally spot welded in. Instead, these are drilled and filled with stainless wire. Why stainless? We’ll come back to that.

(This photo is borrowed from a later step. You can see the weld spots for the rails.)

It goes in this jig, into a furnace at 1550F for 30 minutes, then into a light oil (I use canola oil and automatic transmission fluid). This yields a Rockwell C Scale hardness of 45-47.

This is an alternate way of heat treating I could have done. The fire control group holes are hardened and tempered. You can literally do this with a MAPP torch on a weapon this crude.

I did two of them to this point. One is functional. The other will be deliberately non-functional for costume purposes.

Sandblasted clean for inspection.

Rivet in the front trunnion,

press in a surplus Romanian barrel (A Hungarian is shown. We were building a lot of guns),

the barrel pin, and use a block to neaten up the fitting,

rivet the rear trunnion, and neaten,

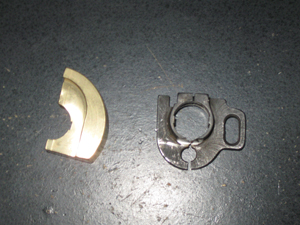

Rivet in the new trigger guard and magazine catch. (Standard steel build shown, brass shown on finished product.) Add a reinforcing plate, not essential, but nice to have.

Rivet the center support.

Now we insert the fire control group (I bought parts, and fabricated other parts for these. The law requires they be US made and semi-auto, to comply with section 922R of the Tax Code (Don’t worry about this unless you’re planning to build one yourself)), check headspace between bolt and breech, and time the mechanism so it actually functions. Springs must be sprung right, alignment, fit, etc. The piston is made from stainless and is another US (commercial) made part.

A Romanian kit set up for test firing is shown.

Sandblast and chemically blast off any contaminants.

Now we phosphate it in hot zinc phosphate.

This darkens the steel and dirties up the brass for that antique look…and those stainless dots stand out like rivets, don’t they?

You’ll notice the new front sight base, in brass. This is pressed on with the hydraulic press and fixed with pins.

As you can see at the top of the page, this stock is designed for short, stocky, malnourished peasants wearing several layers of wool against a Russian winter. Whereas, I’m tall, healthy, reasonably robust and enjoy firing heavy caliber weaponry (Small cannon, by some nations’ laws) while wearing a T shirt.

This will have a much better and much uglier stock. The original was drilled for a cleaning kit and to lighten it. This one will contain pseudo-vacuum tubes and a power switch. I'll redo the buttplate in brass, too.

The original top cover is basic phosphated steel, but it looks much more primitive in brass sheet forged, bent, welded and beaten in place. Some more forging, shaping with a hammer and small anvil block, more shaping, and a nice fit.

The plastic pistol grip will be replaced with a laminated one, eventually.

The so-called gas tube isn’t; it’s merely a shroud for the piston. Add a brass shroud, some vent holes and cooling fins and it’s well on its way to a retro space gun.

The forward grip is held in place with this replacement brass retainer. Also, there’s a new vertical grip of a brass pipe which will eventually contain glowing goo.

The AK’s muzzle brake (Brake, as in brake the hot gases, not break…we don’t want things to break) is effective, but blah. This one is much, much better I think, with bell and reflector that just clears the front sight.

As completed so far:

Voila. It’s still crude and ugly, but with a Victorian future-tech flair, and unlike most props, this one actually shoots.